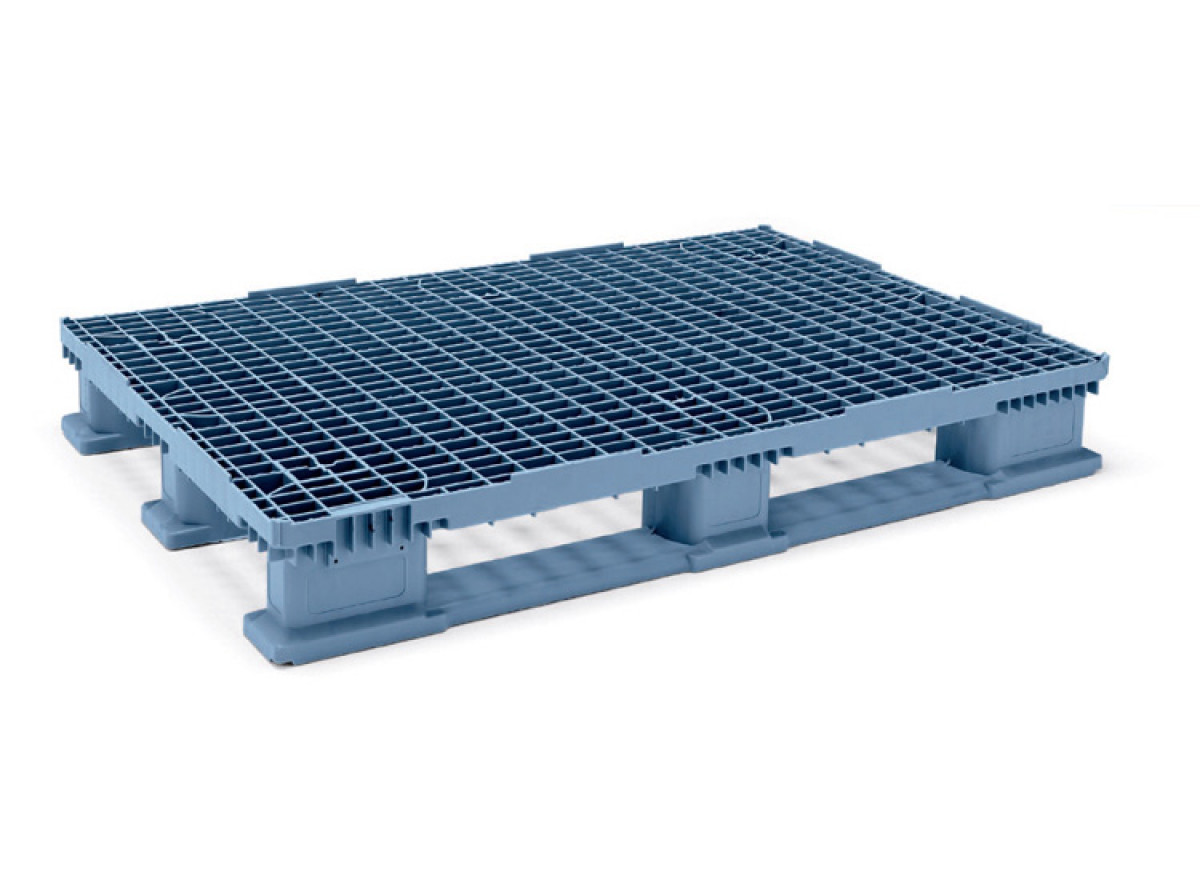

Injection Moulded Products

Phyl pallet is a clean solution suited to safely transport furniture components

Place Friuli Venezia Giulia

Date Thursday 23 November 2017

The challenge

The furniture production business needs tight production and shipping times.

Our customer, a leading manufacturer of furniture doors, needs to improve the storage as well the shipping of lacquered cabinet doors.

Lacquering is a process that requires extreme care and perfect workmanship; the same accuracy must be maintained during palletisation and shipment processes.

The lacquered doors are usually stacked one on top of the other on a wood pallet.

The traditional wood pallet does not fully meet the customer's needs for two reasons: on one side the delicate doors tend to slip from the pallet without edges, being damaged during freight; on the other hand, the wood pallet releases dust and splinters, which can scratch and dirty the product.

Our ad-hoc solution

We have been working closely with furniture manufacturers for many years and we understand very well the needs of this sector.

The solution we proposed to meet the customer’s specific needs is the Phyl pallet equipped with safety edges, to improve stability of the products loaded. We also suggested the use of a pallet-based layer pad to facilitate palletising and de-palletising processes.

This solution offers protection of the product during handling. Moreover, the Phyl pallet is easy to clean, and being made of polypropylene, it is inert, mould and moisture resistant, and does not release fibres or dust.

Phyl pallet is environmentally friendly, since polypropylene is 100% recyclable.